Barcoding & Labeling – Critical Tools in Warehouse Environments

Digital technology is driving significant advances in label manufacturing. Today’s modern warehouses are smart, automated and efficient.

Shelf labeling, tote labeling, cross-docking, picking, packing and shipping are just a few of the applications present in the warehouse that are involved in a successful workflow. Now with the continued growth of e-commerce, we take a look at barcoding technology and how it has become a critical component for maintaining compliance and accuracy in a warehouse environment.

Barcoding and labeling enables efficiency while delivering an accurate inventory count. Warehouse labels help keep the process running smoothly as operations-critical data moves throughout an organization. They are essential for efficient inventory management and the picking process throughout distribution facilities. With the right inventory logging system in place, warehouses can keep ahead of shortfalls or inefficient surpluses. Warehouse labeling also helps maintain correct inventory levels. From barcodes to numeric labeling, a worker in charge of tracking inventory can easily estimate how many of any given item remains on the shelves.

The end goal for manufacturing companies is to have these solutions working together to deliver real-time information for a successful workflow. A successful workflow results in greater efficiency and an increase in profit margins for many years to come.

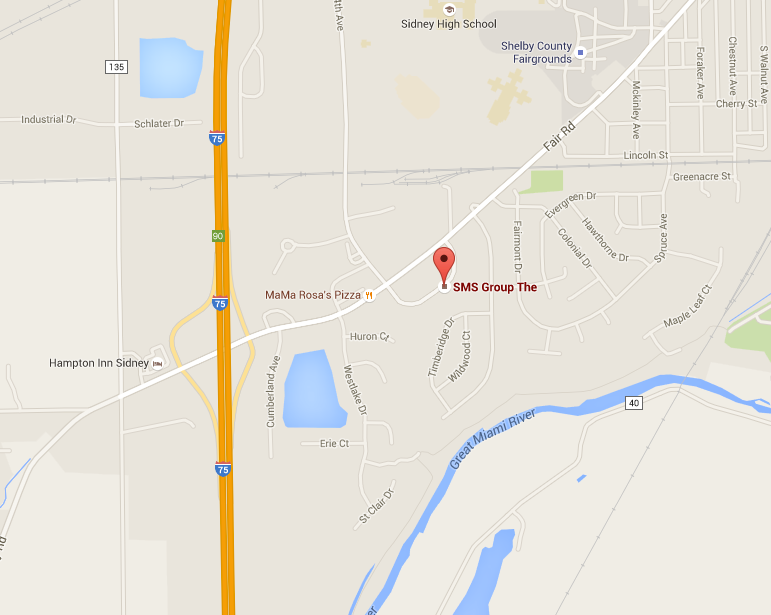

Let SMS Group help

All it takes is finding the right combination of technologies to bring clarity to your business. From the big picture to the crucial details, The SMS Group gives you the power to track, analyze, and improve everything about your shop. Contact us online to learn more or call 937-498-2700.