Securing Your Assets: RFID and Asset Tracking Best Practices

In the dynamic landscape of the modern supply chain, safeguarding valuable assets is paramount. Whether it’s high-value equipment, returnable totes, or other significant inventory items, Radio Frequency Identification (RFID) technology offers a robust solution for asset tracking. Asset tracking is a crucial piece to ensuring that your shop floor is operating efficiently. When it comes to asset tracking, make sure you are following these best practices:

1. Avoid Manual Record Keeping whenever possible

The adoption of RFID technology for asset tracking brings a paradigm shift from traditional methods such as manual record-keeping. The challenges associated with manual processes underscore the need for a more efficient solution.

Efficiency and Accuracy: RFID eliminates the need for labor-intensive manual data entry, significantly reducing human errors. The automation of data collection ensures real-time accuracy in asset tracking, enhancing overall operational efficiency.

Real-time Visibility: Unlike barcodes, RFID allows for the simultaneous scanning of multiple items without direct line-of-sight. This means that entire batches of high-value assets can be tracked instantaneously, providing unparalleled visibility throughout the supply chain.

Streamlined Processes: RFID systems are designed for seamless integration into existing workflows. The technology is user-friendly, requiring minimal training for staff. This simplicity leads to quicker adoption and ensures that proper asset tracking methods become a priority in day-to-day operations.

2. Track Big Ticket Inventory Items with RFID

Managers should recognize that tracking your warehousing equipment is just as critical as tracking the inventory of products or goods for sale. Large, valuable items, such as returnable totes, can be challenging to manage efficiently without a robust tracking system. RFID technology presents an optimal solution by providing real-time visibility into the location and status of these assets. Unlike manual methods, RFID allows for seamless and automatic tracking, minimizing the risk of loss or misplacement. With RFID tags affixed to each tote, businesses can monitor the movement of these high-value items throughout their lifecycle, from shipping to storage and return, ensuring accountability and preventing unnecessary expenses associated with lost assets.

3. Follow Tagging and Labeling Guidelines for Optimal Performance

The effectiveness of RFID asset tracking relies heavily on proper tagging and labeling. Employing the right RFID tags and adhering to guidelines ensures accuracy and efficiency in data collection. For big-ticket items like returnable totes, consider durable and tamper-resistant RFID tags that can withstand the rigors of the supply chain. Proper placement of tags on the items is crucial to guarantee consistent and reliable readings. Adhering to standardized labeling practices and utilizing portal technologies not only enhances the performance of the RFID system but also streamlines the tracking process, reducing errors and improving overall asset visibility.

Let Us Help

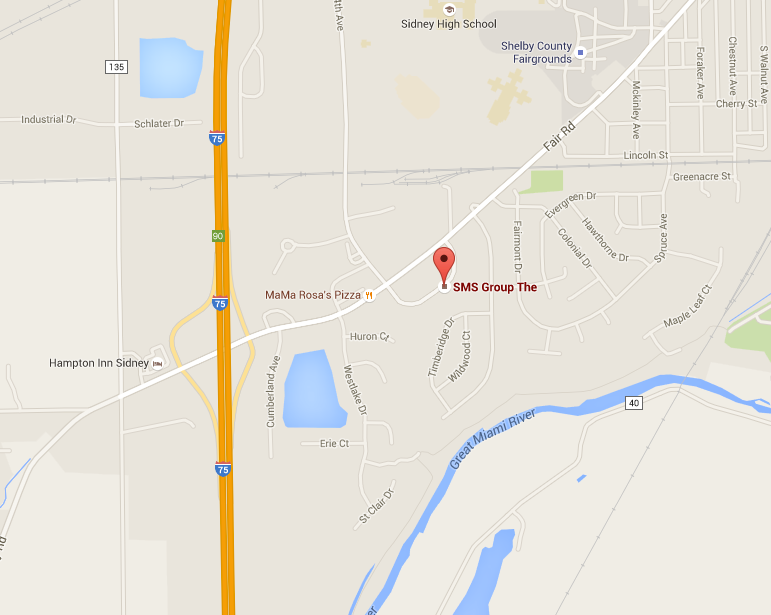

At The SMS Group, we recognize the critical role that effective asset tracking plays in keeping warehouse equipment secure. Our team of supply chain professionals is dedicated to supporting organizations in implementing and optimizing RFID solutions. Have a question about RFID or asset tracking as you strive for operational efficiency? Contact The SMS Group today!